Key Information

Finish

Coverage

Drying Time

Coats

Product Description

PRODUCT DESCRIPTION :-

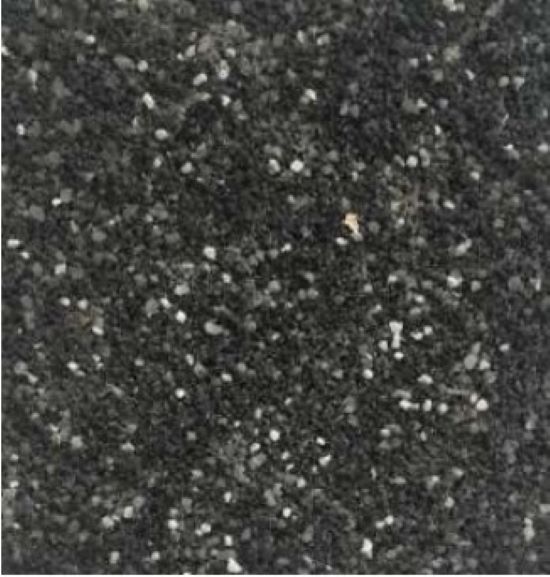

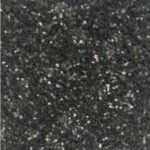

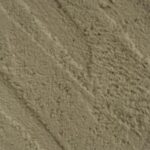

Stone finish is a high-build acrylic texture coating system spray-applied to give a stucco-like 2-mm texture, which will be available in single and multicolour systems. Trowel applied to give a stone-like 2-mm texture, which will be available in single and multicolour systems. These finishes may be over-coated with water-based or solvent-based clear lacquer.

- These Texture finishes will give maximum water proofing to the structure because of its coating system.

- Stone finish is a convenient system for creating a protective and aesthetically pleasing texture finish for most cementitious substrates.

- This offers a choice of finishes which may be left in a matt texture or over-coated by a clear lacquer.

- Being a spray applied texture or trowel applied finish, this allows some degree of inconsistency in the substrate texture and is readily suited to touch up both features resulting in saving time and labour.

- These finishes have a proven track record for over many years of resisting extreme weather condition.

- These finishes are water-based for applicator safety and ease of use.

- To achieve indicated performance, surface preparation must be carried out according to the company recommendations.

- The surface must be free from dust, dirt, grease, oil and other contaminants that may interfere with adhesion.

- Fresh cementitious substrates should be left for 14 days before coating.

These finishes will be available in single and multi-colour systems. These finishes will minimize the degree of surface preparation required and allows some surface imperfections to be filled.

SURFACE PREPARATION :-

Surface Preparation is the responsibility of the Builders, Renovator or Main Contractor and the Applicator. To achieve the indicated performance, it must be carried out according to company’s recommendations.

The surface must be free from dirt, dust, grease, oil, mould release agents, bond-breakers and other contaminants that may interfere with adhesion. Fresh cementitious substrates should be left for 14 days before coating. There must be less than 15% moisture in the surface at the time of coating to ensure optimum coating performance.

APPLICATION :-

It is recommended that application be carried out by a skilled applicator, who is totally conversant with products and systems. After thorough mixing, the material is applied as a thin coat (priming coat) on the surface and the second coat is applied to achieve the required pattern (by trowel/spray gun). Stone finish is not suitable for walk-on surfaces.

TOP COATING :-

- 100% Pure Acrylic Emulsion Paint is specifically recommended as an overcoat in high pollution or heavy traffic areas (only in case of non-natural coatings).

- For natural inbuilt colour coatings, no paint is required.

- For deep tones and accent colours, company recommends the application of Semi-Acrylic Emulsion paint having Low-Sheen/Satin/Gloss.

Product Reviews